Views: 484 Author: Uniwell Wirings Publish Time:2023-09-22 12:34:46 Origin: Uniwell Wirings

1. Conventional automotive wiring harness processing, insulating rubber is made of new antioxidant PVC material, while the core conductor is made of oxygen-free copper or silver-plated copper, or tin-plated. Copper, through the precision equipment carefully made.

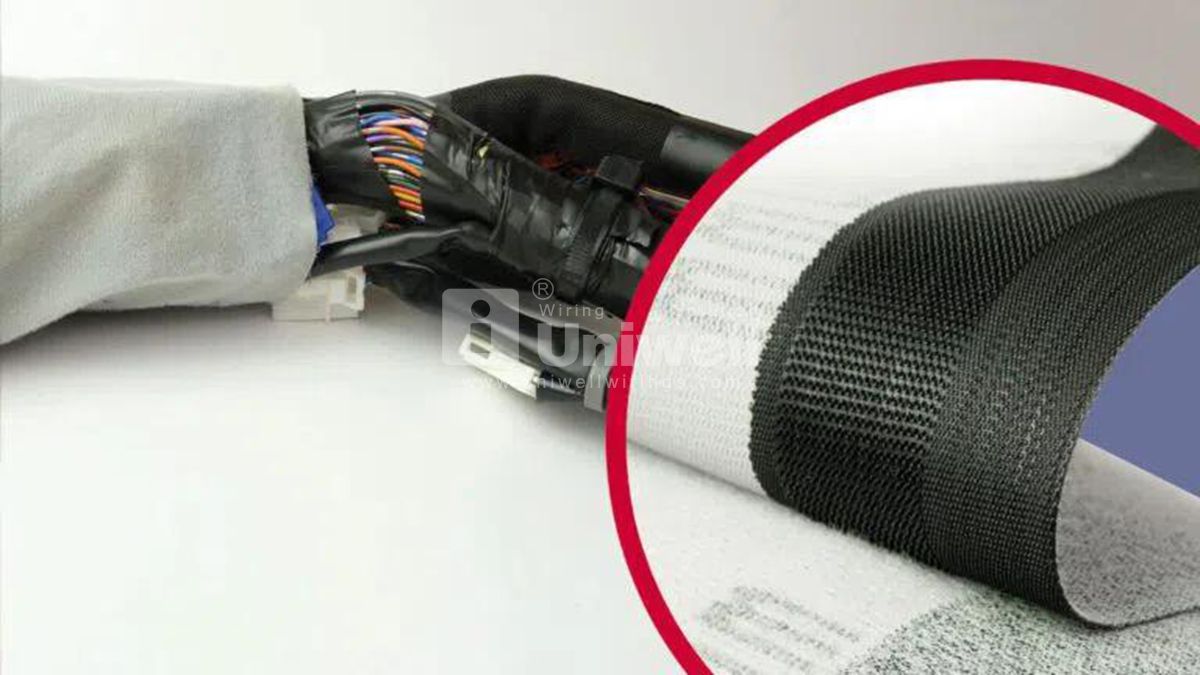

2. High quality automotive wiring harnesses are very good in heat resistance and insulation, and their core wires are used for seven strands or braided, so that there can be enough density to reduce the capacity, resistance value and inductance of the automotive wiring harnesses, so that they can output enough current.

3. Because of the temptation of automotive wiring harnesses, there are some informal manufacturers, their insulating rubber is recycled PVC plastic, and the core conductor is recycled copper, or steel wire, recycled copper, copper-clad aluminum, and so on. Some use a mixture of these materials. Most consumers know that these conductors have greater internal resistance and higher voltage drop than oxygen-free copper, which is harmful to the 12V automotive power.

4. To determine the quality of automotive wiring harness processing, not only to look at its appearance and size, but more importantly, to look at the quality and thickness of the copper core inside the automotive wiring harness. Because some automotive wiring harness processing makes the rubber thicker, and the inner core of the copper core becomes thinner, so the two are disproportionate, so the size of the cut surface of the copper core confirms this.

Automotive wire harness machining has the following requirements:

1. Opening Process. The accuracy of the opening process is directly related to the overall production schedule. Once an error occurs, especially if the opening dimensions are short, it will lead to rework of all stations, which will take time and effort to affect productivity. Therefore, in preparation for the opening process, it is important to rationalize the opening size and dimensions of the wire in accordance with the attached diagram.

2. Crimping process. Determine the crimping parameters according to the terminal types required by the drawings and produce a crimping operation manual. For special requirements, indicate and train operators in the process documentation. For example, some wires need to pass through the sheath before crimping. It needs to be pre-assembled and returned from the pre-installation station and then crimped. In addition, penetrating crimps use special crimping tools. The crimping method has good electrical contact characteristics.

3. Pre-installation process. First, a pre-installation process operation manual should be compiled. In order to improve the assembly efficiency, complex wiring harnesses must be equipped with a pre-installation station. The rationality of the pre-installation process directly affects the efficiency of the overall assembly and reflects the skill level of the craftsman. If the pre-installation portion of the component is too small or the assembly is not wired properly, the workload of the total assembly crew will increase and the speed of the assembly line will be slowed down. Therefore, process personnel should remain on site frequently to summarize the process.

4. Assembly process. It can be programmed according to the assembly board of the product development department, design tools and equipment, material box size, and connect all component sheaths and accessory numbers to the material box to improve assembly efficiency. Compiles the assembly content and requirements for each workstation and balances the entire assembly station to prevent overloading the workload and slowing down the entire assembly line. In order to balance workstations, craftsmen must familiarize themselves with each operation and measure work time in the field and adjust the assembly process at any time.